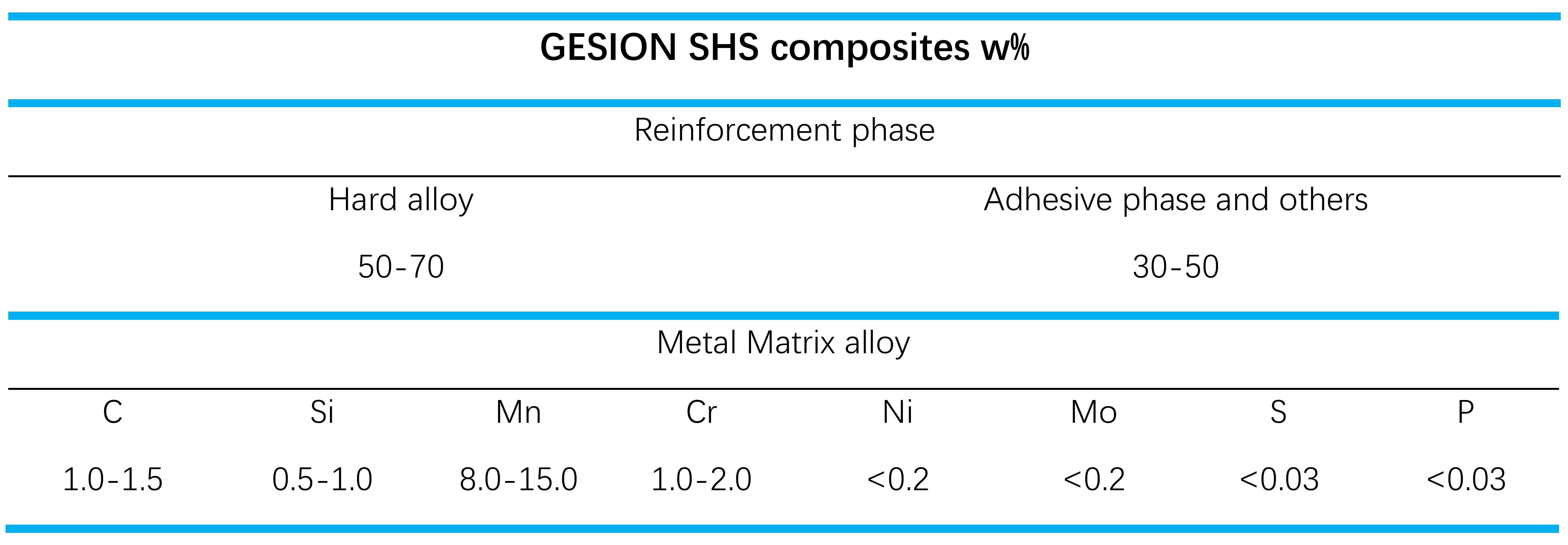

Self-Propagating High-Temperature Synthesis (SHS) technology utilizes the exothermic nature of chemical reactions, sustaining combustion waves independently. By controlling parameters such as self-sustaining reaction velocity, combustion temperature, and conversion rate, this advanced material preparation technique yields products with specified compositions and structures. Leveraging this technology, GESION manufactures particle-reinforced metal-based surface composite materials, which combine the high wear resistance and strength of ceramic reinforcement phases with the high ductility and toughness of alloy steel matrices. This provides excellent comprehensive performance with strong-tough bonding, a feature not typically found in single-material solutions. Additionally, it effectively addresses the contradiction between strength and toughness, with surface wear resistance being 3-10 times that of the base material. Compared to simple methods like melting and casting with externally added hard phase particles, this product resolves issues such as inadequate reinforcement phase content, uneven distribution, poor wetting with the matrix, and weak bonding with the substrate, which can lead to peeling.